Now on WUFI!

#IMCasestudy3 Everton Heath: Passivhaus Standard Build School

"I’m absolutely amazed at how quick the installation of Passive Purple was and what it actually does for a building. I had no idea! I’m looking forward to this school lowering energy consumption."

View Downloadable PDF

Fast and Reliable Shipping Across the United States

Seamless shipping experience, no matter where you're located!

-

Overview – Precision Airtightness with Passive Purple Brush

They say, “The devil is in the detail,” and nowhere is that more true than in high-performance construction. Achieving exceptional airtightness doesn’t happen by chance—it’s the result of meticulous preparation and the right materials.

On every project, we begin with Passive Purple Brush, a high-performance liquid-applied membrane designed to seal critical junctions and eliminate air leakage pathways. This innovative airtightness solution is the foundation for meeting—and often exceeding—the required air test scores. By creating a seamless, durable barrier at the earliest stages, we set the entire build up for long-term energy efficiency, improved comfort, and compliance with the most demanding building standards, including Passivhaus.

-

Background – Sealing OSB Joints for Superior Airtightness

In modern timber construction, Oriented Strand Board (OSB) joints are one of the most common sources of unwanted air leakage. Left untreated, these gaps can compromise the building envelope, increase energy loss, and make achieving high-performance airtightness targets far more difficult.

Our solution starts with Passive Purple Brush, a high-performance liquid-applied airtight membrane. This advanced coating is meticulously applied to every OSB joint, junction, and penetration, creating a continuous, flexible, and durable airtight seal. By addressing these high-risk leakage points at the source, we eliminate draughts, improve thermal performance, and safeguard the building’s energy efficiency for the long term.

The result? Consistently high air test scores that don’t just meet industry standards—they often exceed the stringent Passivhaus requirement of 0.6 ACH. This meticulous approach ensures every project we work on benefits from a robust, future-proof airtight envelope.

-

Solution – Passive Purple Brush for Complete Airtight Sealing

From the very first stage of construction, we make Passive Purple Brush a core part of our airtightness strategy. This high-performance liquid-applied membrane is meticulously applied to all critical junctions, including OSB joints, nail heads, service penetrations, and window and door reveals. Every application is designed to eliminate potential air leakage points before they can compromise the building envelope.

This precision-driven process ensures our projects consistently achieve—and often surpass—the required air test scores, including the demanding Passivhaus airtightness standard. Beyond airtightness, Passive Purple Brush also plays a vital role in enhancing energy efficiency, preventing moisture ingress, and creating a healthier indoor environment.

By combining the right products with rigorous application techniques, we deliver airtight building envelopes that support long-term sustainability, reduced energy consumption, and exceptional year-round comfort for occupants.

-

Results – Record-Breaking Airtightness with Passive Purple Brush

Once applied, Passive Purple Brush creates a robust, flexible, and long-lasting airtight membrane that adapts to natural building movements and withstands environmental changes without losing its integrity. This durability is key to maintaining airtightness performance over the lifetime of the building.

On this Passivhaus-standard school build, we achieved an exceptional airtightness score of just 0.03 ACH (air changes per hour)—a result far exceeding both UK Building Regulations and the stringent Passivhaus requirement of 0.6 ACH.

This outstanding performance was made possible by Passive Purple Brush’s fibre-reinforced polymer technology, which ensures a consistent seal across all joints, penetrations, and reveals. The result is a high-performance building envelope that delivers:

-

Ultra-low energy consumption

-

Exceptional thermal comfort

-

Reduced carbon footprint

-

Long-term protection against air and moisture ingress

This project is a clear demonstration of how detailed preparation and high-quality airtightness products can achieve world-class results in real-world construction.

-

-

AIR TESTING

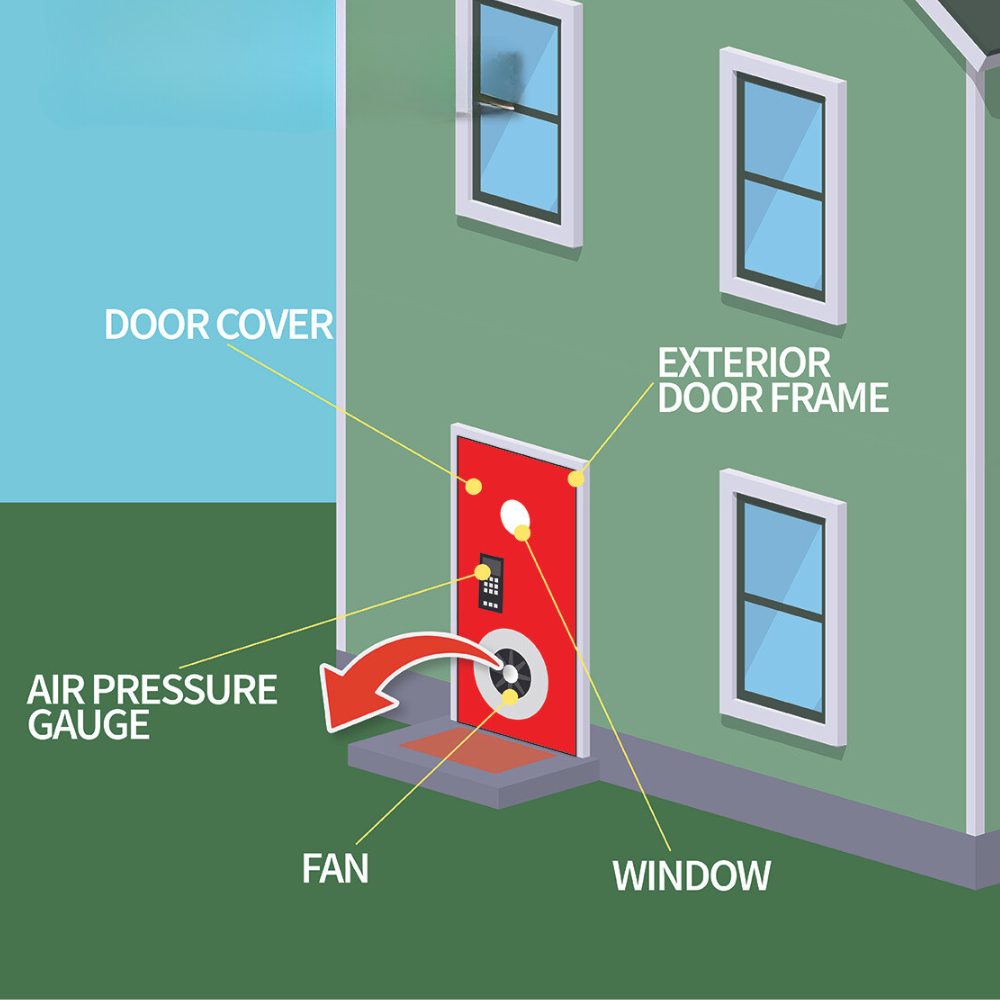

Air testing- also known air testing, air permeability testing, air leakage testing, and air pressure testing- measures the amount of air escaping through a buildings envelope.

-

Client Feedback – First-Hand Experience with Passive Purple Airtightness

“I’m absolutely amazed at how quick the installation of Passive Purple was and the incredible difference it makes to a building’s performance. I had no idea airtightness could have such a big impact! The process was efficient, precise, and clearly carried out with real expertise. I’m excited to see how this school benefits from reduced energy consumption, improved comfort, and long-term sustainability.”