Now on WUFI!

"High-Performance Airtightness" "High-Performance Airtight Construction"

"With all the different obstacles in the way, by form of different construction materials, I’m so impressed with the liquid membrane that was used. It’s going to save us so much money!"

View Downloadable PDF

Fast and Reliable Shipping Across the United States

Seamless shipping experience, no matter where you're located!

-

Overview – Ensuring Airtightness and Vapour Control in a Norwich New Build

This Norwich new build presented a unique challenge: vapour control and airtightness hadn’t been considered during the early construction stages. By the time we were brought on board, multiple substrates and junctions needed sealing, each with its own potential for air leakage. The question was clear – could Passive Purple handle such a varied and complex application?

The answer was a resounding yes. With its versatility, strong adhesion to multiple surfaces, and proven performance in airtightness and vapour control, Passive Purple was the ideal solution to create a continuous, high-performance building envelope.

-

Background – Sealing Multiple Substrates for a Continuous Airtight Barrier

This Norwich new build came with a wide variety of substrates to address — from PIR insulation boards and spray foam insulation to OSB sheathing and exposed steelwork. Each surface posed its own airtightness challenges, requiring a flexible yet reliable approach.

To overcome these complexities, we used a combination of Passive Purple Internal Vapour Control for large surface coverage and Passive Purple Brush for intricate detailing. This dual-product method allowed us to create a truly continuous airtight seal around every joint, penetration, and material junction.

The result? A seamless “purple line” visible throughout the entire building, marking a fully connected airtight envelope that performs consistently across all substrates.

-

Challenges – Tackling Complex Airtightness in a Multi-Substrate Build

This Norwich new build wasn’t short on complexity. From the outset, our team faced a wide range of materials to seal — including PIR boards, spray foam insulation, OSB panels, and exposed steelwork. Steel presented one of the biggest hurdles, as creating a continuous vapour control layer around rigid metal structures required precision detailing and creative application techniques.

By combining Passive Purple Internal Vapour Control for large surface areas with Passive Purple Brush for intricate detailing, we meticulously sealed every junction, penetration, and transition point. This method ensured there were no gaps, no thermal bridges, and no opportunities for moisture or air to bypass the barrier.

As the project took shape, a continuous “purple line” emerged across the structure — a visible marker of determination, precision, and airtight performance. Despite the challenging mix of substrates, our installers maintained airtightness without compromise, achieving the high-performance standards demanded by modern energy-efficient building design.

-

Solution – Achieving Ultra-Low Airtightness with Passive Purple

This Norwich new build achieved an outstanding Passivhaus-certified airtightness score of just 0.03 ACH — that’s 20 times lower than the already stringent Passivhaus requirement of 0.6 ACH. This result demonstrates the unmatched performance of Passive Purple airtight membranes in even the most complex builds.

Whether your goal is to meet full Passivhaus certification or simply build to a Passivhaus standard, Passive Purple provides the airtightness guarantee you need. Our proven installation methods ensure a score of 0.6 ACH or lower, delivering:

-

Exceptional thermal efficiency

-

Significant reductions in heating and cooling demand

-

Superior comfort for building occupants

-

Long-term protection against draughts, condensation, and energy loss

Passive Purple isn’t just a product — it’s a complete airtightness solution, designed to perform across multiple substrates and building types.

-

-

Results – Exceptional Airtightness Achieved Despite Late-Stage Installation

On this Norwich new build, we achieved an airtightness score of 0.5 ACH (air changes per hour) — an impressive result, especially considering airtightness was only addressed later in the construction process.

By applying Passive Purple Internal Vapour Control and Passive Purple Brush across multiple challenging substrates, we created a continuous airtight barrier that met and exceeded UK building regulation requirements. This result delivers:

-

Lower heating and cooling costs through reduced air leakage

-

Improved indoor comfort with consistent temperatures and no draughts

-

Better moisture control, preventing condensation and mould

-

Long-term durability of the building envelope

This case proves that even when airtightness is not considered from day one, Passive Purple airtight membranes can still deliver outstanding performance — ensuring energy efficiency, occupant comfort, and a future-ready building.

-

-

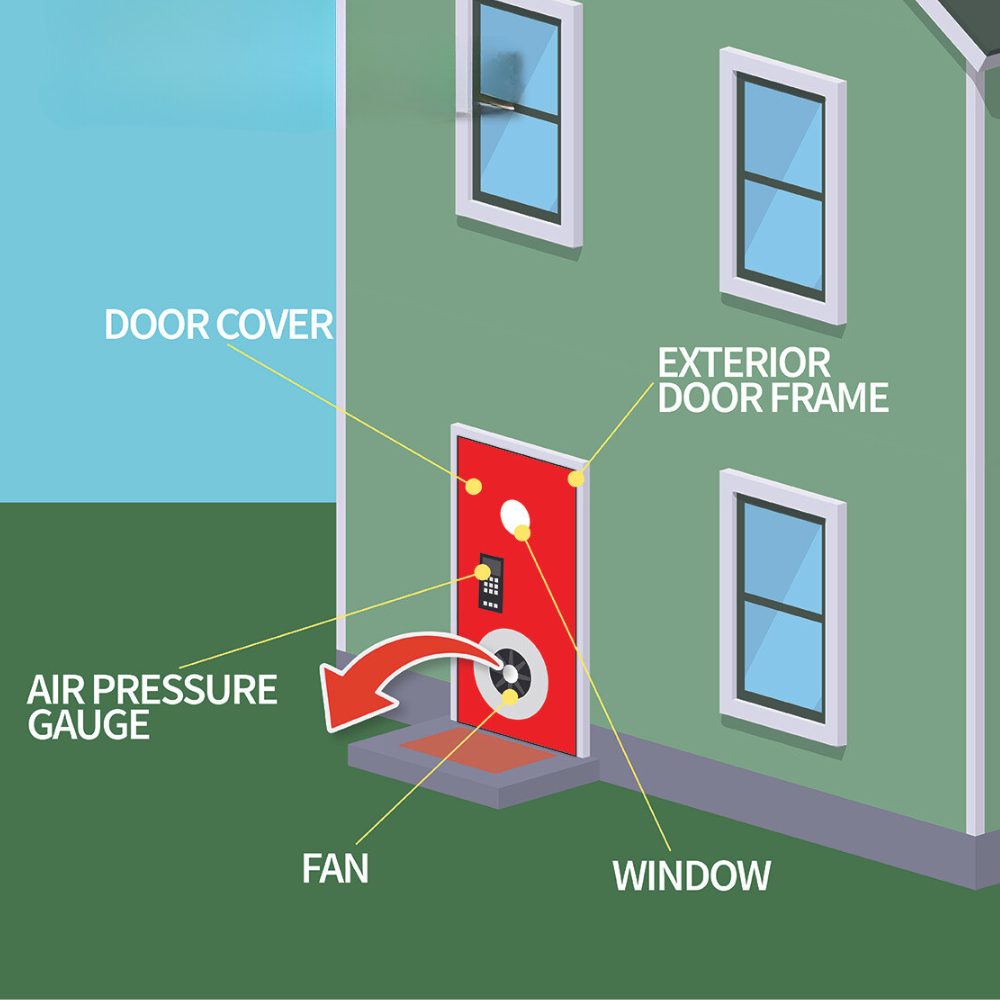

Air Testing

Air testing- also known air testing, air permeability testing, air leakage testing, and air pressure testing- measures the amount of air escaping through a buildings envelope.

Products Used on This Project – Passive Purple Airtightness Solutions By Intelligent Membranes

To tackle the complex mix of substrates on this Norwich new build, we relied on a combination of high-performance Passive Purple products:

-

Passive Purple Internal Vapour Control Layer – Spray-applied to create a seamless, durable, and highly effective airtight barrier across walls, ceilings, and complex junctions.

-

Passive Purple Brush – Perfect for sealing intricate details, penetrations, OSB joints, steel connections, and other hard-to-reach areas.

-

Airtight Fleece Tape – Applied to vulnerable edges and tricky junctions to reinforce airtightness and ensure continuous protection.

This product combination delivered exceptional air leakage prevention, moisture control, and long-term durability — even on a project where airtightness was introduced late in the build.